Mining and Exploration Business.

continuously creates and grows shareholder and stakeholder value

through sustainable exploitation of mineral resources.

setup

continuously creates and grows shareholder and stakeholder value

through sustainable exploitation of mineral resources.

About Golden Reef Mining

Extracting minerals with latest techniques

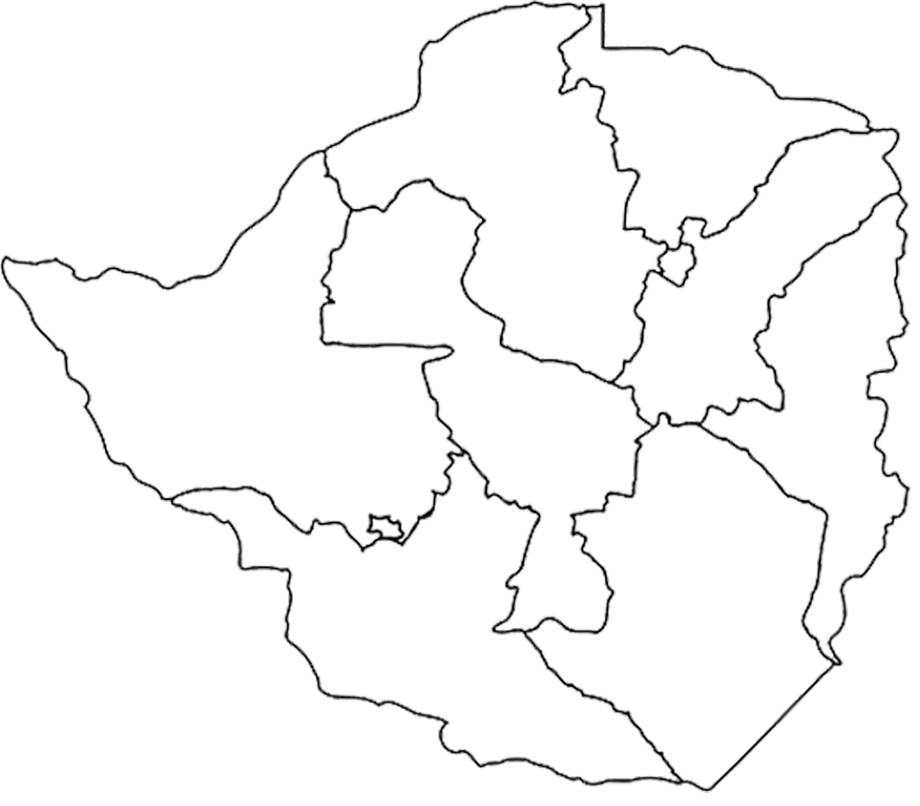

Golden Reef Mining (GRM) is a Zimbabwe based private limited minerals exploration and mining company with a diversified mineral portfolio. The company was established and incorporated in 2007. Golden Reef Mining (Private) Limited is in the business of mining and exploration of selected mineral deposits.

We have established whole production chain, of which main products cover gold and chrome mining.

Service Request

Our history

Celebrating GRM Milestones

Strength to strength within the industry

Golden Reef Mining (GRM) is a Zimbabwe based private limited minerals exploration and mining company with a diversified mineral portfolio. The company was established and incorporated in 2007. Golden Reef Mining (Private) Limited is in the business of mining and exploration of selected mineral deposits. The company has strategically secured mineral rights within Zimbabwe associated with known mineralization where potential remains for resource extensions. In these areas significant grassroots exploration works were undertaken by other previous mineral resource companies.

Strength to strength within the industry

Various publications related to the mining and mineral industries were brought out. Offices were set up into the different parts of the country close to major mining centers. We’re promoting the awareness about protection of environment.

Strength to strength within the industry

Started imparting training to the industry personnel in the preparation of mining plans and also in the other fields. Awareness amongst all the sections of the mining industry, necessity and advantages of the truly systematic mining

Strength to strength within the industry

Clientele seeking technical consultancy covers wide spectrum of small and large mines and many public sector organizations. It has been able to provide useful information to the industry through its Minerals Data Bank of the country.

Strength to strength within the industry

The first being the processing and approval of mining plans & schemes of mining for all the mines in the countries and very second one being the implementation of rules for the protection. Personnel in the mining plans and also in the other fields.

what we provide

Our Offerings

125 +

Creative ideas

Empowers people of team by adding strength to their abilities of teamwork and productivity.

100 +

Social Responsibility

We bring back to the communities in several ways

10 +

Domestic operations

Economic transaction mining project that going to take place inside geo graphical boundaries.

Pheobe

Gold

Mutorashanga

Chrome

Flexiburg

Gold

Ruia

Gold

Shashi

Gold

BSR